RPET is recycled polyethylene terephthalate, which is an environmentally friendly material.

The production process of RPET is made from discarded polyester fibers, such as waste plastic bottles. Firstly, clean the waste thoroughly and remove impurities. Then crush and heat it to turn it into small particles. Subsequently, the particles are melted and regenerated, colored powder is added, and stretched and refined through a fiber spinning machine to produce RPET fibers

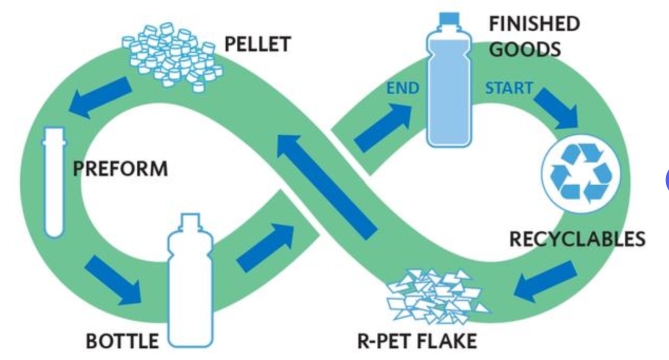

The production of rPET T-shirts can be divided into four major links: raw material recycling → fiber regeneration → fabric weaving → ready-to-wear processing.

1. Raw material recovery and pretreatment

• Plastic bottle collection: Collect waste PET bottles through community recycling points, supermarket reverse logistics or professional recycling enterprises (about 14 million tons of PET bottles are produced worldwide every year, and only 14% of which are recycled).

• Cleaning and crushing: The recycled plastic bottles are sorted manually/mechanically (remove impurities, non-PET materials), remove the labels and caps (mostly PE/PP materials), wash and remove residual liquids and stains, and then crush them into 2-5cm fragments.

2. Fiber regeneration (RPET yarn production)

• Melt extrusion: After drying, the PET fragments are heated to 250-280℃ to melt, forming a viscous polymer melt.

• Spinning molding: The melt is extruded into a fine stream through the spray plate, and after cooling and curing, it forms a recycled polyester short fiber (or directly spun into a continuous filament).

• Spinning: short fibers are made into RPET yarn through combing, striping, coarse yarn, fine yarn and other processes (similar to the original PET yarn process, but the raw material is recycled).

3. Fabric weaving and Clothing processing

• Fabric weaving: RPET yarn is made of knitted fabric through circular machine/transverse machine weaving (consistent with the process of ordinary polyester fabric), which can be made into different tissues such as plain, pique, ribbed, etc.

• Post-processing and sewing: similar to ordinary T-shirts, including dyeing, cutting, printing, sewing (neckline rib/edge), ironing and other steps, and finally making RPET T-shirts.

RPET T-shirt is a typical landing product of “plastic recycling economy”. By converting waste plastic into clothing, it takes into account environmental protection needs and practical value.

Post time: Jun-18-2025